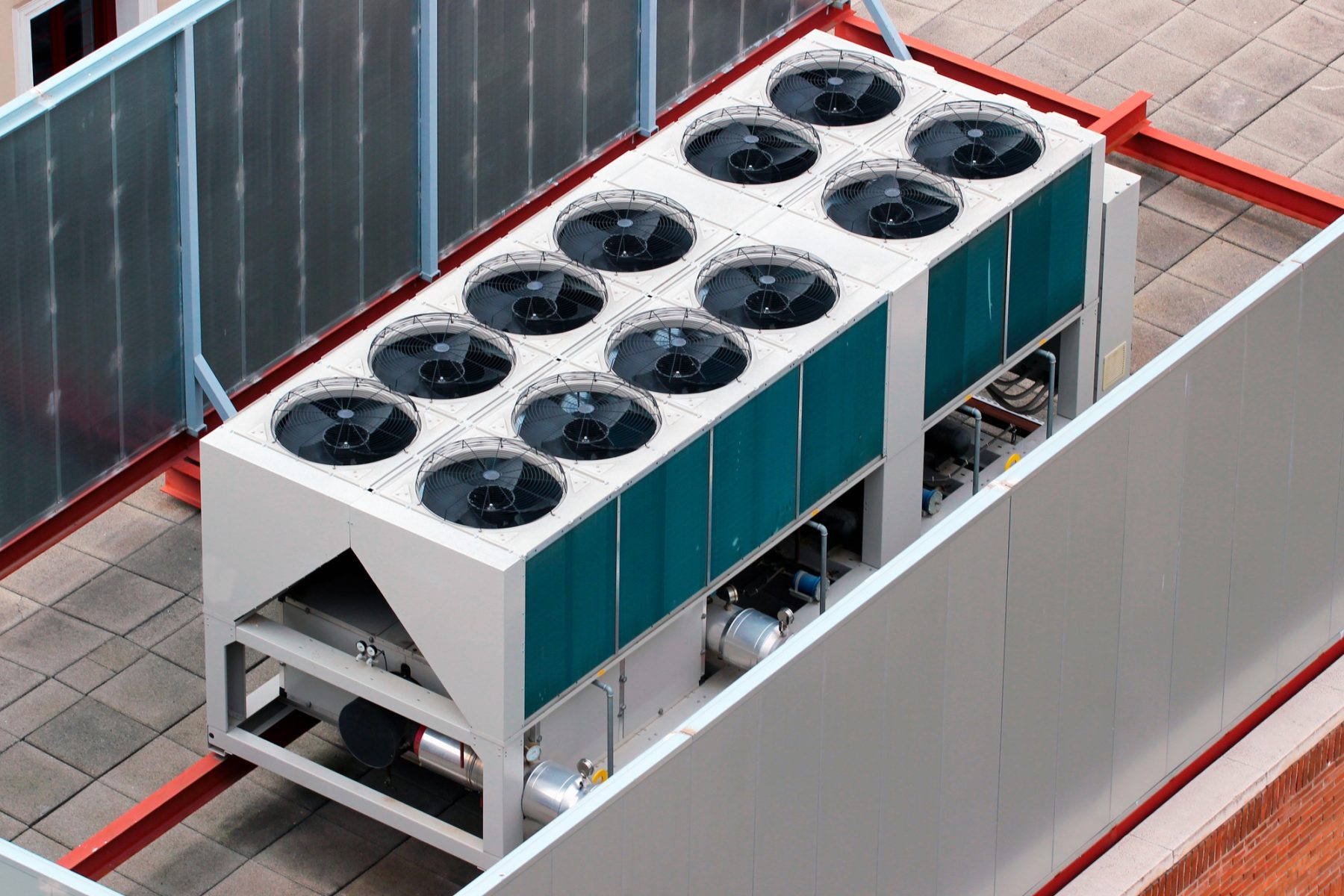

Soluzioni evolute per la gestione dei sistemi ventilanti nel settore HVAC&R

Scopri la gamma Selpro. Soluzioni standard e prodotti personalizzati sulle specifiche esigenze di ogni cliente.

Al servizio di costruttori e installatori per fornire risposte e risolvere problemi

Aiutiamo i costruttori a implementare nuove funzioni e a migliorare l’efficienza.

Supportiamo il lavoro di costruttori di macchine industriali o componenti con soluzioni su misura in grado di offrire prestazioni superiori.

Semplifichiamo il lavoro degli installatori con soluzioni Plug & Play

Grazie alla semplicità di configurazione, l’installazione è accessibile a tutti i professionisti, anche senza formazione specifica.

Massima efficienza e controllo con i software Selpro

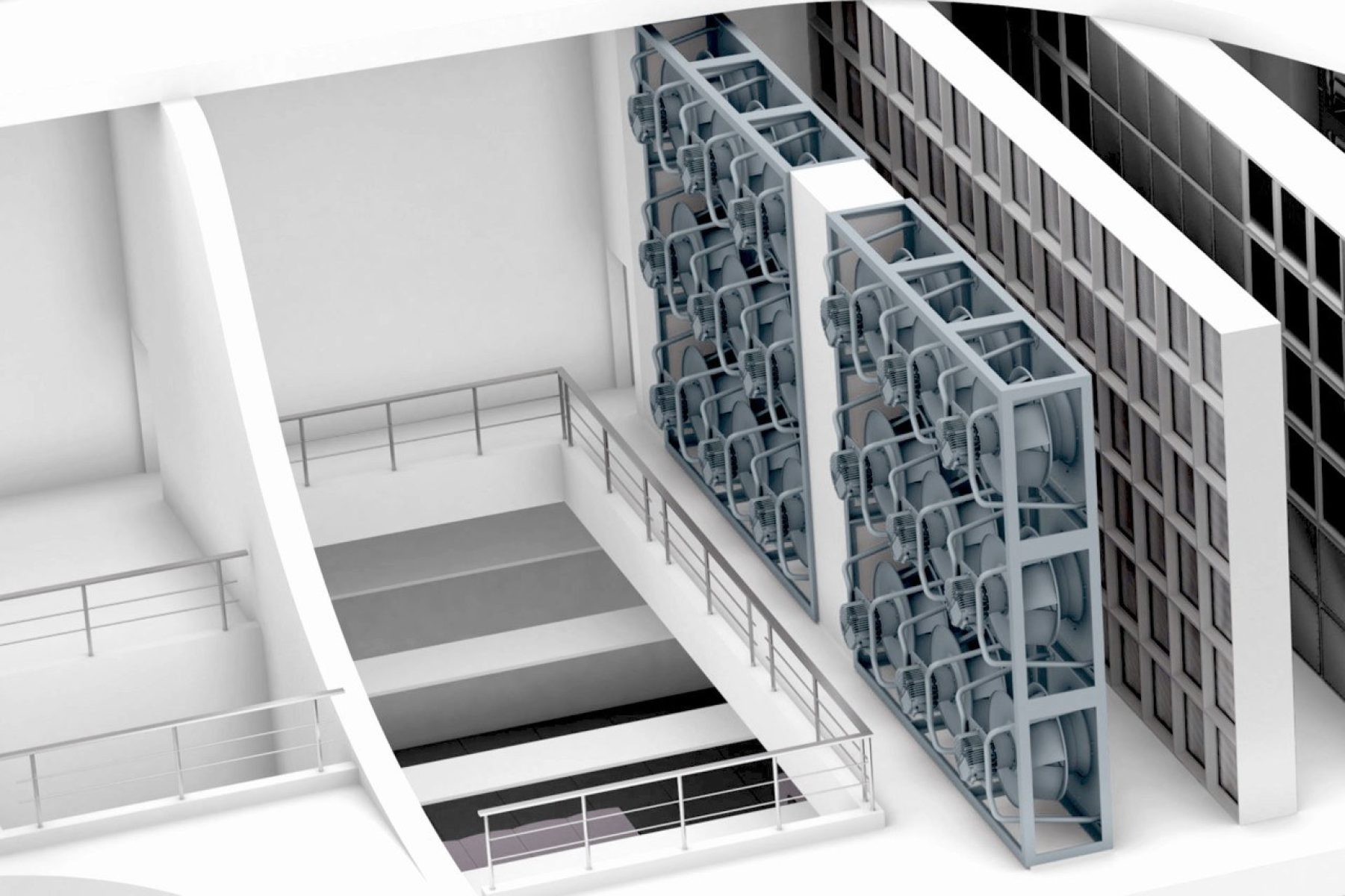

Soluzioni avanzate per il collaudo, la diagnostica e il monitoraggio remoto, progettate per ottimizzare i sistemi ventilanti EC e i regolatori Selpro, ridurre i tempi di fermo e supportare la manutenzione predittiva attraverso dati strategici.

Prodotti innovativi che diventano standard di settore

Ricerca, tecnologia, innovazione continua.

Grazie a un’esperienza specialistica al servizio di costruttori e installatori, Selpro ha sviluppato nel tempo una selezione di prodotti di ultima generazione che risolvono problemi concreti in modo efficace nel settore HVAC&R.

Prodotti e software esclusivi che garantiscono efficienza e durabilità, in tanti ambiti diversi.

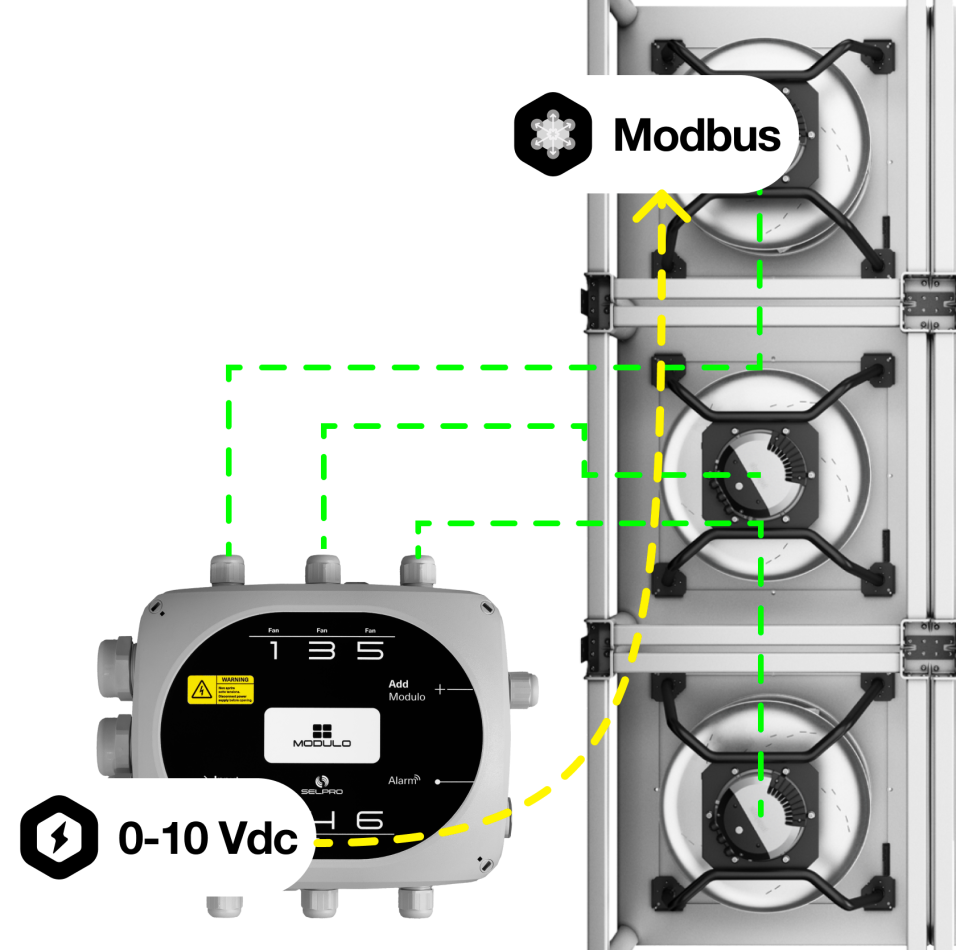

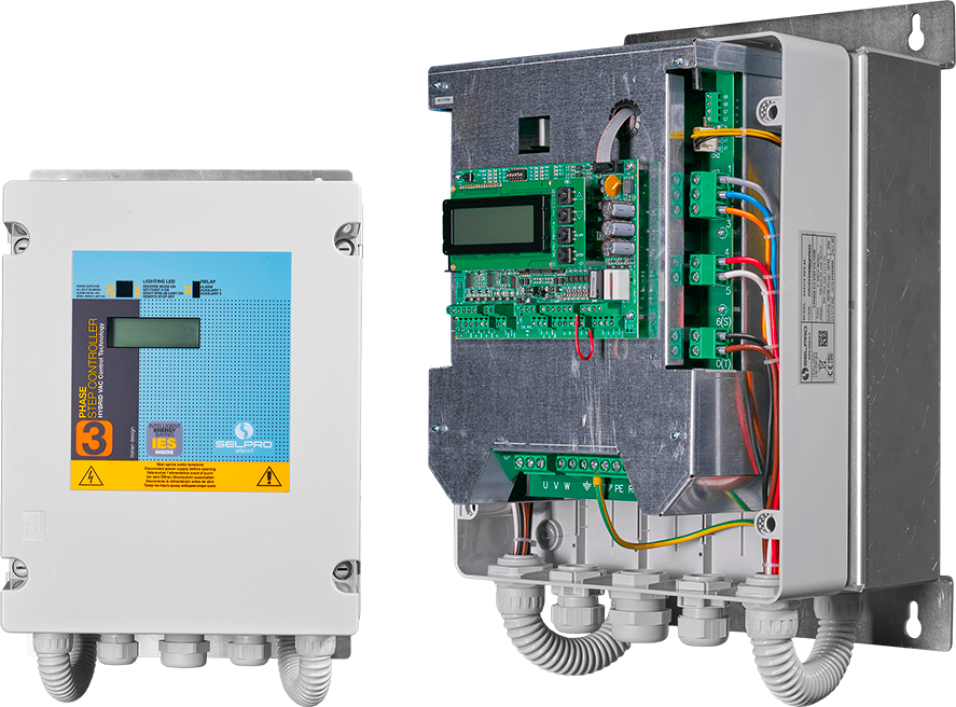

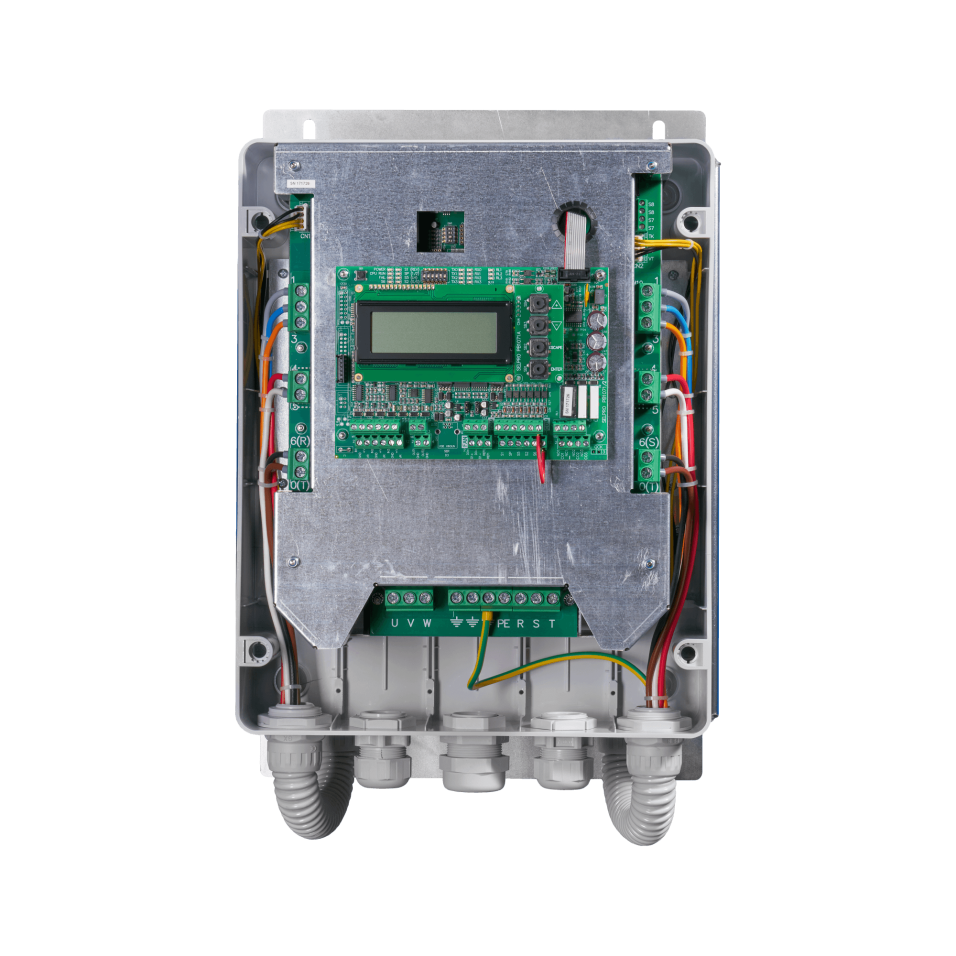

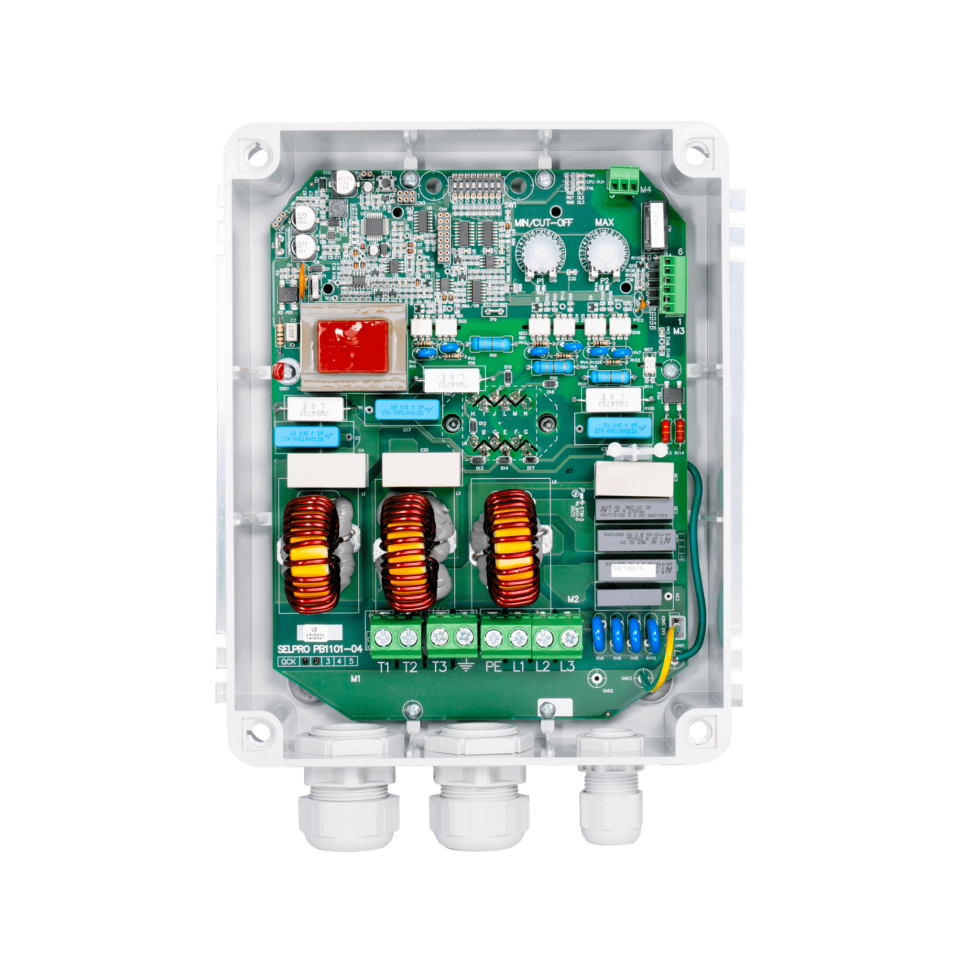

Per motori AC/EC e impianti adiabatici

Scopri tutti i nostri dispositivi di regolazione di sistemi di ventilazione, personalizzabili in base alle specifiche necessità di ogni cliente.

ECM

DSV

VTS

Totale flessibilità per adattarsi a ogni impianto

Quadri elettrici su misura, sviluppati attorno al tuo sistema

Quadro è la linea Selpro di quadri elettrici Serie Q, progettati per garantire massima affidabilità e flessibilità, con elettronica avanzata e personalizzazione su misura.

Selpro, una storia di eccellenza ed evoluzione continua

Con oltre 40 anni di esperienza, Selpro è oggi un punto di riferimento nel settore per tutte le realtà che cercano non solo un fornitore ma un partner nello sviluppo di soluzioni elettroniche.