Regolazione avanzata per motori EC e Sistemi Adiabatici

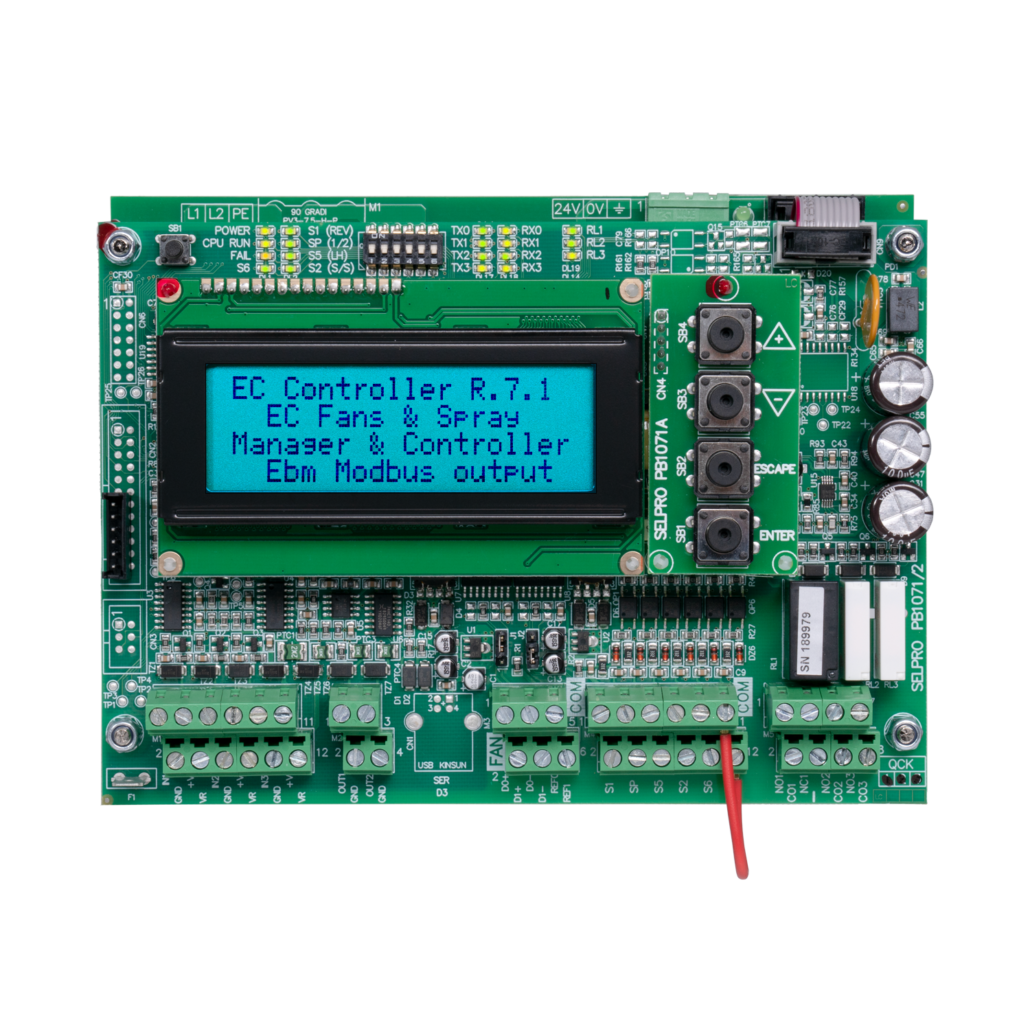

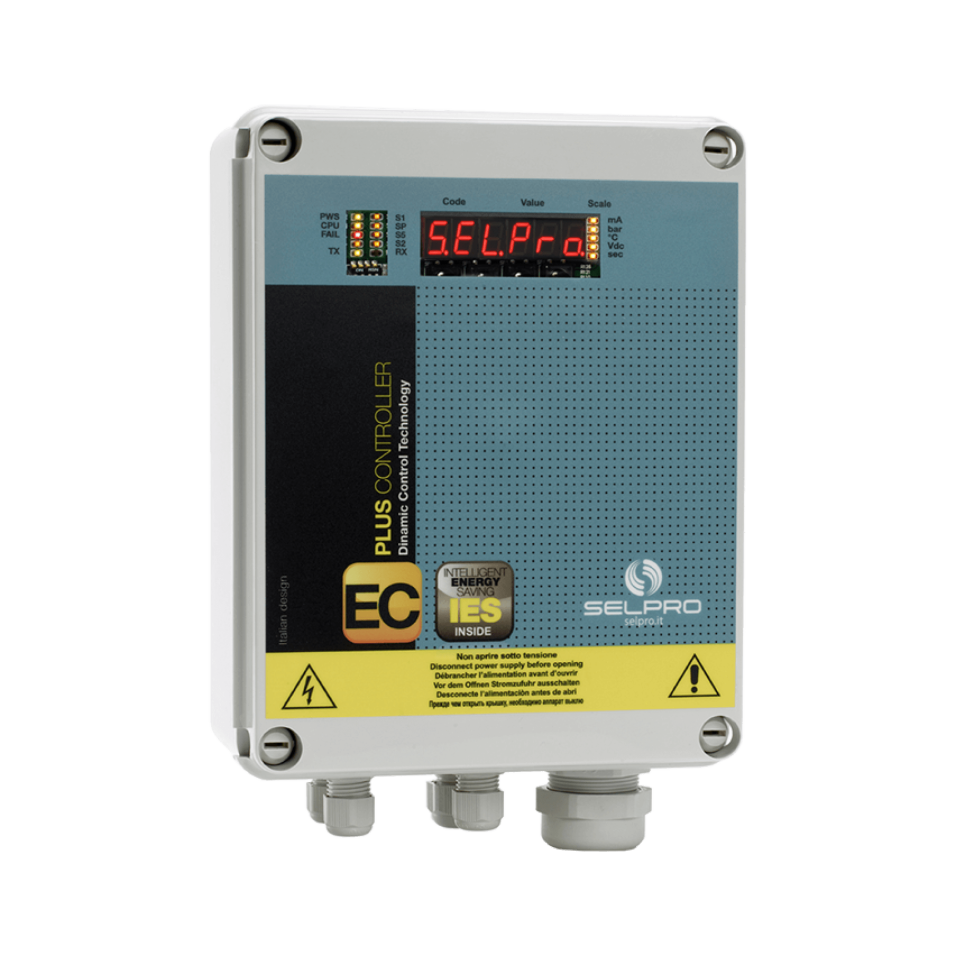

EC-Manager è un regolatore elettronico avanzato, progettato per il controllo preciso e dinamico dei motori EC in applicazioni HVAC/R quali drycooler, condensatori, Fan-Grid e unità di trattamento aria. Basato su comunicazione Modbus RTU, garantisce regolazione continua e omogenea, monitoraggio intelligente e integrazione completa con sistemi BMS.

È omologato dai principali costruttori di motori EC, tra cui ebm-papst e Ziehl-Abegg, assicurando piena compatibilità e interoperabilità. I protocolli di comunicazione sono sempre disponibili e attivabili facilmente tramite switch, semplificando installazione, avviamento e assistenza.

Gestisce fino a 32 ventilatori EC su 247 indirizzi, con controllo diretto della velocità via Modbus e/o comando analogico 0-10Vdc. Il controllo è silenzioso, progressivo e ottimizzato, contribuendo al risparmio energetico e al comfort acustico.

Flessibilità operativa e personalizzazione:

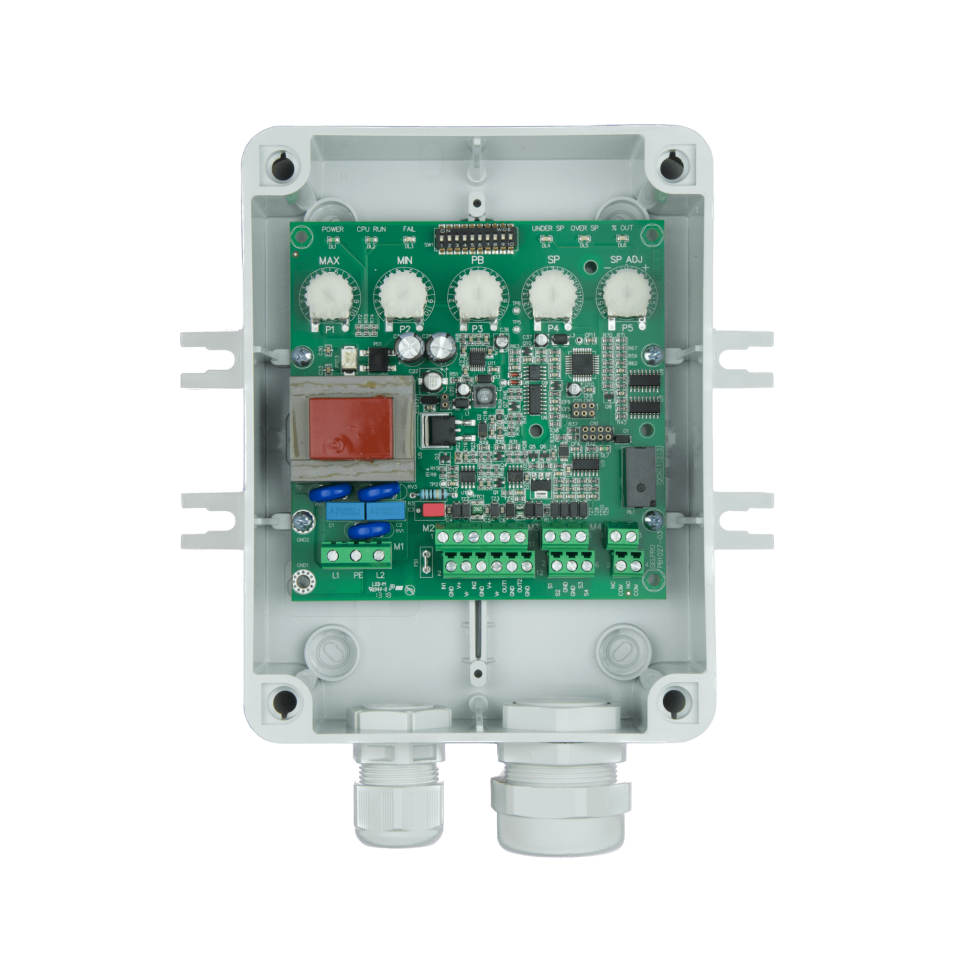

Offre modalità operative selezionabili tra Master PID, Master proporzionale e Slave proporzionale, oltre a 13 configurazioni predefinite per un rapido adattamento alle diverse applicazioni. È possibile gestire 2 setpoint indipendenti e 2 banchi di parametri personalizzabili, per la definizione di limiti, soglie e comportamenti dinamici su misura.

Gestione intelligente dei sistemi adiabatici:

ECM è strutturato per il controllo evoluto dei drycooler wet & dry, attivando il raffreddamento evaporativo in base a temperatura, umidità o orari programmati, garantendo un funzionamento efficiente e coordinato tra ventilazione e sistema ad acqua.

Diagnostica avanzata e affidabilità:

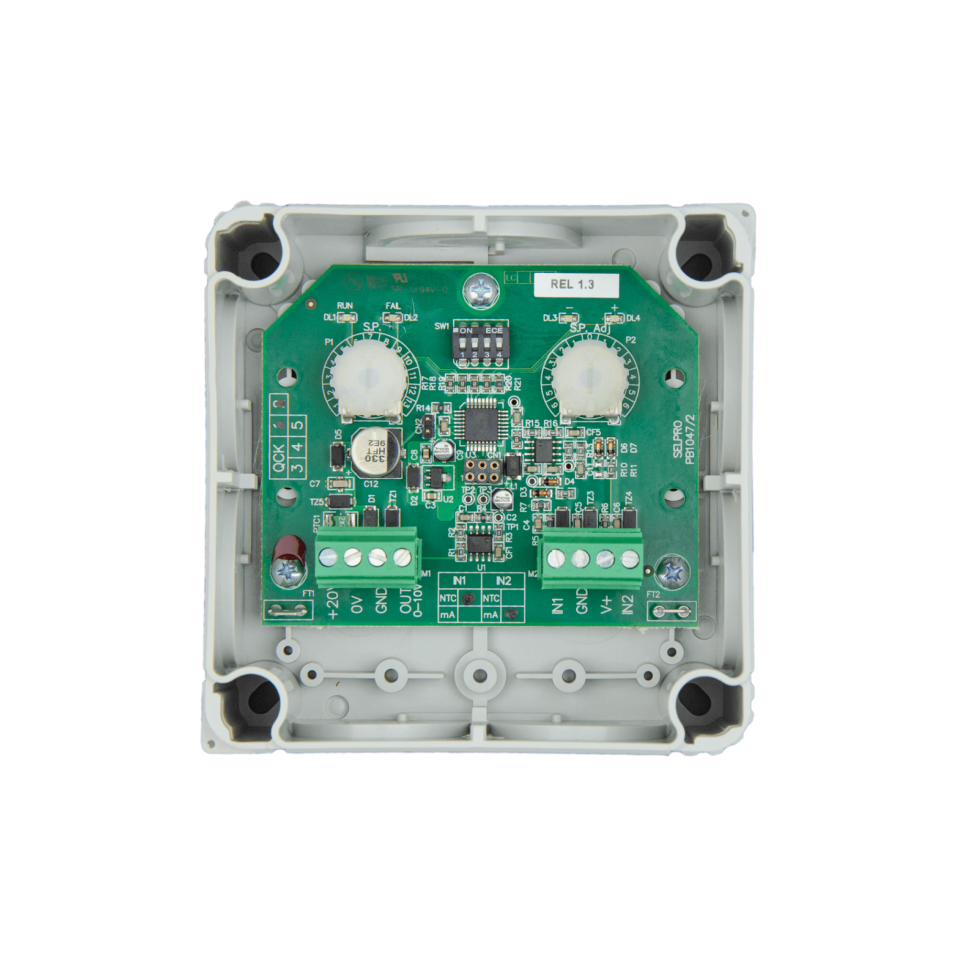

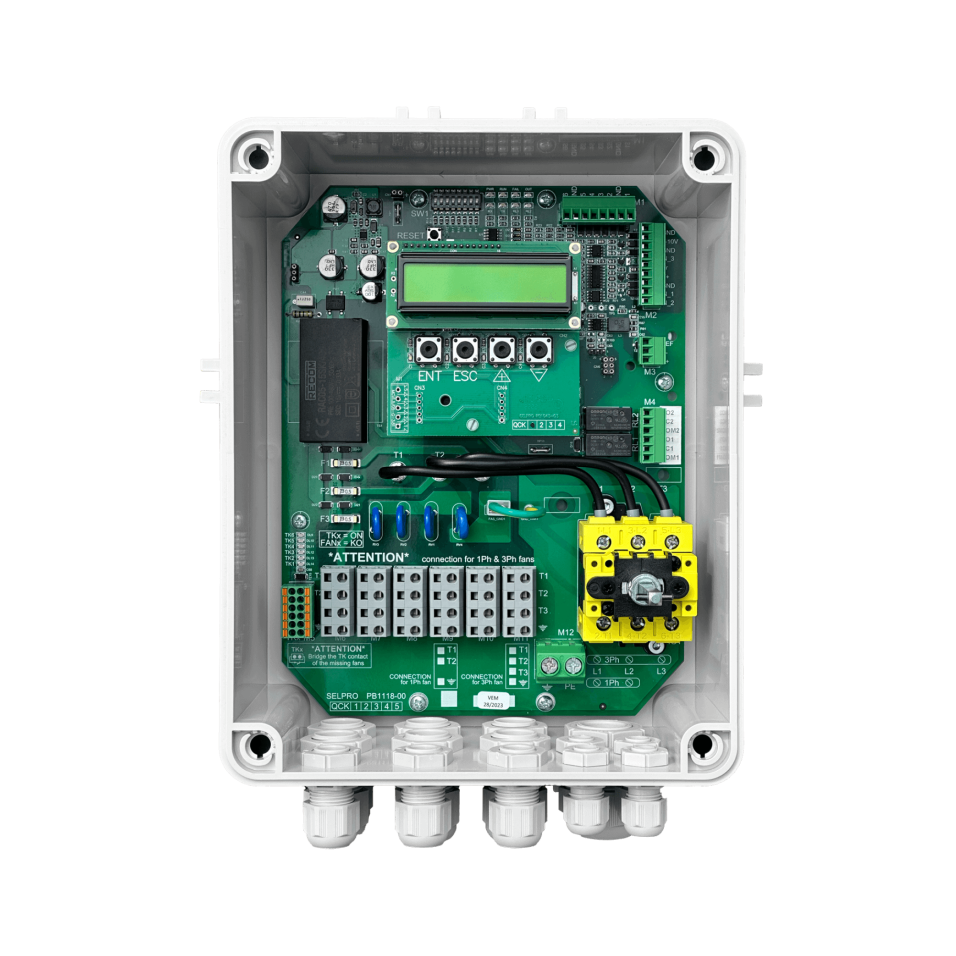

È dotato di registratore eventi con orologio interno (RTC) per la tracciabilità di errori, stati e transizioni operative. Disponibile in versione DIN-rail o per esterno con protezione IP55, è progettato per operare in ambienti gravosi grazie alla protezione contro sovratensioni, sovraccarichi e interferenze EMC.

EC-Manager è la soluzione completa per il controllo efficiente, affidabile e intelligente dei motori EC e dei sistemi di raffreddamento avanzati.

Ingressi, uscite e connettività

- 2 ingressi analogici configurabili compatibili con trasduttori 4-20mA, 0,5-4,5V e sonde NTC (-10° / 90°C); in modalità slave, accetta anche 0-10V e 0-20mA.

- ingresso analogico per funzioni speciali di lettura e/o regolazione da remoto.

- Interfaccia Modbus RTU isolata e dedicata alla connessione con i ventilatori in rete Modbus

- Interfaccia Modbus RTU isolata e dedicata alla connessione con Master/BMS remoto.

- 2 uscite 0-10V programmabili per dispositivi slave o sistemi adiabatici

- 6 contatti ausiliari ON/OFF programmati per le diverse operatività funzionali

- 3 relè configurabili per la gestione degli Allarmi, dei Warning e del sistema adiabatico.

Caratteristiche speciali

- Attiva cicli periodici di lavaggio delle batterie per mantenere le prestazioni dello scambiatore.

- Evita le possibili pendolazione del sistema, regola gradualmente l'attivazione o disattivazione dei singoli ventilatori per ottimizzare la potenza ventilante ed adeguarla alle minime necessità di esercizio.

- Esegue accensioni temporizzate dei motori per eliminare l’umidità, inserendo rotazioni alternate per prevenire il blocco delle pale e presenza ghiaccio.

- Riduce la velocità massima dei ventilatori in orari programmati per diminuire rumore notturno e ridurre i consumi.

- Seleziona automaticamente il banco di parametri di lavoro per la regolazione in base alla temperatura esterna rilevata.

- Esegue un ciclo di pulizia automatica a intervalli programmabili per migliorare l'efficienza e ridurre gli interventi di manutenzione.

- Modifica il Setpoint dinamicamente in funzione delle variazioni di temperatura rilevate.

- Consente il controllo remoto del Setpoint tramite segnali analogici esterni (0-10V o 4-20mA)

- Garantisce il funzionamento di sicurezza in caso di perdita del segnale principale, utilizzando parametri di emergenza.

- Funzione sempre attiva per prevenire danni ai componenti.